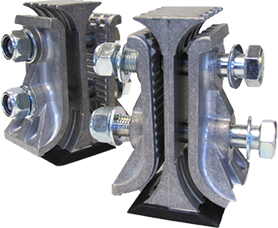

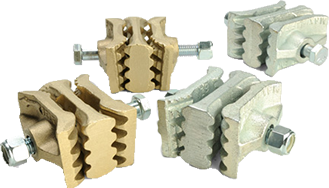

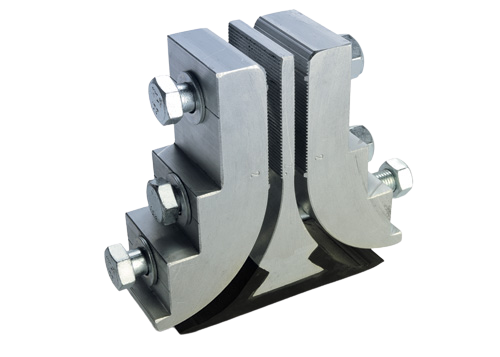

Belt Splices

Maxi-Lift offers a complete line of mechanical belt splices engineered for long-lasting performance and ease of installation. Select your belt splice to learn more.

Contact a Sales Rep

Subscribe

Join our mailing list to stay up to date with what is happening at Maxi-Lift, Inc.