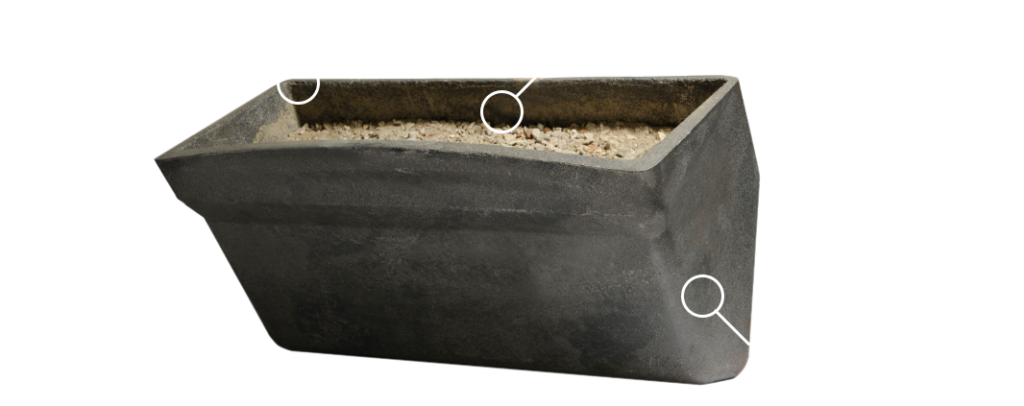

- Mill duty, thick walls with reinforced back and corners

- Extremely high impact and abrasion resistance

- Applications up to 600 degrees

- Non-corrosive, non-sparking

- Designed to handle sand, glass cullet, stone, shot blast, rock, concrete and other abrasive products.

- Overview

- Size Chart

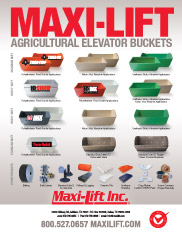

- Uses

- Venting

- Media / Literature

The DI-MAX AC style ductile iron elevator buckets are engineered to exceed the performance requirements of any industrial application. These buckets are designed with thicker walls and a reinforced front lip to increase bucket life in tough industrial environments. Ductile iron is far superior to malleable iron in both impact and abrasion resistance. Replacing malleable iron with DI-MAX ductile iron elevator buckets will result in longer bucket life and more efficient operation.

The DI-MAX AC style ductile iron elevator buckets are engineered to exceed the performance requirements of any industrial application. These buckets are designed with thicker walls and a reinforced front lip to increase bucket life in tough industrial environments. Ductile iron is far superior to malleable iron in both impact and abrasion resistance. Replacing malleable iron with DI-MAX ductile iron elevator buckets will result in longer bucket life and more efficient operation.

Other Considerations

DRILLING: Elevator buckets are manufactured without a drill pattern. Special drilling or punching can be accommodated upon customer request.

VENTING: AC Style Ductile Iron Buckets are cast with vent holes included. More vent holes may be added at additional cost.

DIGGER BUCKETS: Use slightly larger metal digger elevator buckets to help loosen material in the elevator boot section that has set up or hardened, thereby reducing abrasion on the plastic buckets. Call for details on Metal Digger elevator bucket options.

SPACING: PROJECTION x 2 = STANDARD VERTICAL SPACING (depending on material and speeds, smaller and large spacing may be used).

INSTALLATION: Use a #1 standard elevator bolt or Sabre-Tooth elevator bolt for installation. Designed to be used with fender or flat and lock washers and hex or locking nuts. If buckets are being installed on chain, use hex head bolts, nuts and washers.

FDA: Both the urethane and polyethylene are designed to FDA specifications for direct contact with food products. Special food grade nylon is also available for high heat applications.

DI-MAX AC Size Chart

| BUCKET SIZE, INCHES | THICKNESS | WEIGHT, LBS. | CAPACITY, CU. IN. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bucket Size | Length | Projection | Depth | Back Wall Thickness | Front Corner Thickness | Front Lip Thickness | Water Cu. Inches X-X | 100% Gross Cu. Inches X-Y | ||||

| in. | mm | in. | mm | in. | mm | |||||||

| 12 X 8 | 12-1/2 | 318 | 9-1/4 | 235 | 9 | 229 | .425 | .575 | .550 | 28 | 368.9 | 472.4 |

| 16 X 8 | 16-1/2 | 419 | 9-1/4 | 235 | 9 | 229 | .425 | .600 | .550 | 38 | 508.1 | 651.4 |

| 18 X 10 | 18-3/4 | 476 | 11-1/2 | 292 | 11 | 279 | .550 | .675 | .700 | 70 | 874.5 | 1139.2 |

| 24 X 10 | 24-3/4 | 629 | 11-3/4 | 298 | 11 | 279 | .410 | .725 | .600 | 72 | 1231.6 | 1570.9 |

Recommended Uses

(Recommended but not restricted to handling these specific products)

Aggregate

Cement

Coal

Fertilizer

Gravel

Perlite

Potash

Sand

Sawdust

AC Style Ductile Iron Buckets are cast standard with 4 vent holes with 2-5/8″ centers and 1/4″ bolt holes. More vent holes may be added at additional cost.

DI-Max AC Industrial Buckets

There's Ductile Iron Then There's Maxilift Ductile Iron

The DI-MAX AA bucket performs at the top of its class

Complete your Build

A single shipment, on a single invoice, from a single source: Maxi-Lift. For a limited time only, Maxi-Lift is offering 3% OFF on new bundle orders. Contact us today or call (800) 527-0657 for more information!

Subscribe

Join our mailing list to stay up to date with what is happening at Maxi-Lift, Inc.