- Patented, Heavy Duty Design

- Nests for Economical Packing and Shipping

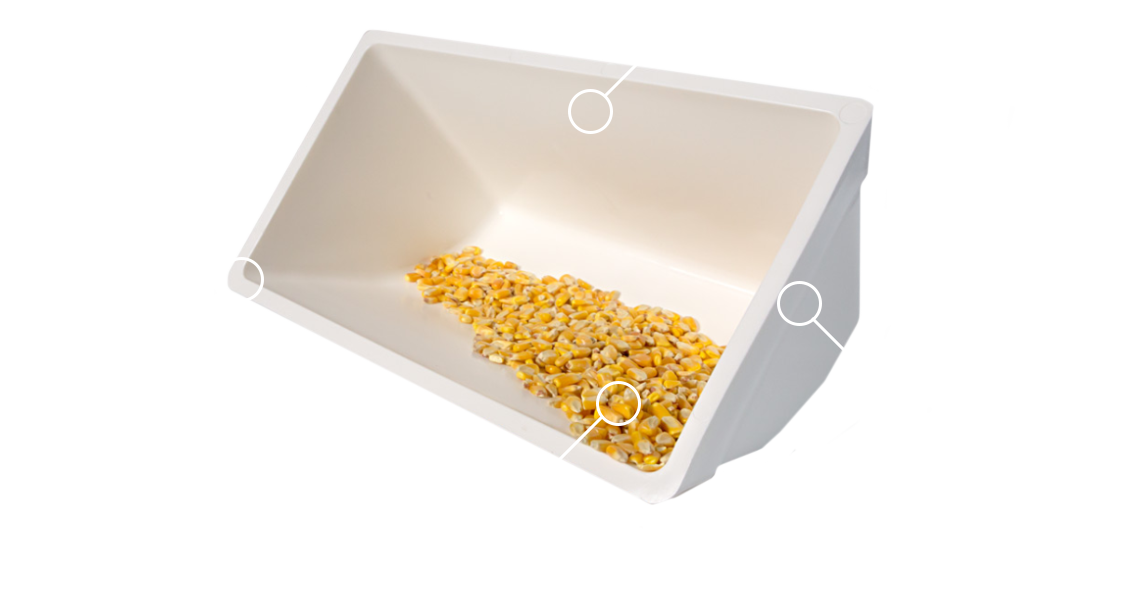

- Thick Wear Lip and Corners

- Stocked Around the Globe

- Calumet Shape for Clean Filling and Discharge

- Overview

- Size Chart

- Size Chart (Low Profile)

- Uses

- Materials

- Venting

- Media / Literature

The HD-STAX is a patented stackable elevator bucket designed for long life, more capacity, and economical shipping. Designed to stack (nest) together, the HD-STAX gives you almost 3 times more buckets per skid and container. The HD-STAX buckets slide together to provide up to 60% space reduction for storage and shipping resulting in lower costs.

The HD-STAX is a patented stackable elevator bucket designed for long life, more capacity, and economical shipping. Designed to stack (nest) together, the HD-STAX gives you almost 3 times more buckets per skid and container. The HD-STAX buckets slide together to provide up to 60% space reduction for storage and shipping resulting in lower costs.

The HD-STAX also features a thicker, heavier wear lip molded across the front and sides of the bucket, for a tougher, stronger and longer lasting design. The wear lip is almost 2” tall, and is thicker in the corners to give you sustainable life when used in tough agricultural applications.

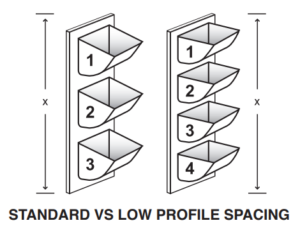

HD-Stax Low Profile Option

A reduced height for closer vertical spacing allows more buckets per foot of elevator belt. When upgrading to HD-Stax Low Profile buckets, horsepower requirements must be evaluated due to increased capacity.

Other Considerations

DRILLING: Elevator buckets are manufactured without a drill pattern. Special drilling or punching can be accommodated upon customer request.

VENTING: Available as needed. See venting options in our catalog.

DIGGER BUCKETS: Use slightly larger metal digger elevator buckets to help loosen material in the elevator boot section that has set up or hardened, thereby reducing abrasion on the plastic buckets. Call for details on Metal Digger elevator bucket options.

SPACING: See elevator bucket spacing details in the size chart (depending on materials and speeds, smaller and larger spacing may be used).

INSTALLATION: Use a #1 standard elevator bolt or Sabre-Tooth elevator bolt for installation. Designed to be used with fender or flat and lock washers and hex or locking nuts. If buckets are being installed on chain, use hex head bolts, nuts and washers.

FDA: Both the urethane and polyethylene are designed to FDA specifications for direct contact with food products.

U.S. Patent D748157, Patent MX 48375, Ⓓ Maxi-Lift, Inc., Community Registered Design No. 002683862-0001, China Patent Marking: ZL 201530103355.9

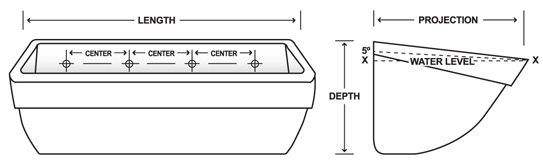

HD-Stax Size Chart

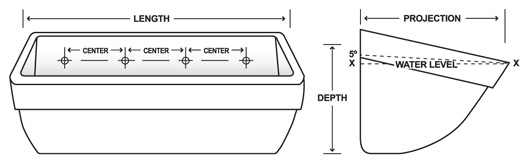

| BUCKET SIZE | PUNCHING | WEIGHT, LBS. | CAPACITY, CU. IN. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bucket Size | Length | Projection | Depth | Back Wall Thickness | Centers | # of Holes | Bolt Size | Top Down | HDPE | Water Level | Usable 5 Deg. | Std Spacing | |||

| in. | mm | in. | mm | in. | mm | ||||||||||

| 4 x 3 | 4-1/4 | 108 | 3-5/8 | 92 | 2-7/8 | 73 | 0.25 | 2-1/4 | 2 | 1/4 | 7/8 | 0.22 | 16 | 18 | 4 |

| 5 x 4 | 5-5/8 | 143 | 4-5/8 | 118 | 4 | 102 | 0.32 | 3-3/16 | 2 | 1/4 | 1-1/8 | 0.47 | 38 | 42 | 5 |

| 6 x 4 | 6-5/8 | 168 | 4-5/8 | 118 | 4 | 102 | 0.32 | 4-3/8 | 2 | 1/4 | 1-1/8 | 0.55 | 46 | 51 | 5 |

| 7 x 4 | 7-5/8 | 194 | 4-5/8 | 118 | 4 | 102 | 0.32 | 2-5/8 | 3 | 1/4 | 1-1/8 | 0.61 | 52 | 57 | 5 |

| 6 x 5 | 6-3/4 | 172 | 5-3/4 | 146 | 5 | 127 | 0.35 | 4-3/8 | 2 | 1/4 | 1-5/8 | 0.81 | 72 | 79 | 6 |

| 7 x 5 | 7-3/4 | 197 | 5-3/4 | 146 | 5 | 127 | 0.35 | 2-5/8 | 3 | 1/4 | 1-5/8 | 0.92 | 85 | 94 | 6 |

| 8 x 5 | 8-3/4 | 222 | 5-3/4 | 146 | 5 | 127 | 0.35 | 3-1/16 | 3 | 1/4 | 1-5/8 | 1.00 | 103 | 113 | 6 |

| 9 x 5 | 9-3/4 | 248 | 5-3/4 | 146 | 5 | 127 | 0.35 | 3-1/2 | 3 | 1/4 | 1-5/8 | 1.10 | 110 | 121 | 6 |

| 8 x 6 | 8-11/16 | 221 | 6-7/8 | 175 | 6-1/8 | 156 | 0.36 | 3-1/16 | 3 | 1/4 | 1-5/8 | 1.39 | 140 | 154 | 7 |

| 9 x 6 | 9-11/16 | 246 | 6-7/8 | 175 | 6-1/8 | 156 | 0.36 | 3-1/2 | 3 | 1/4 | 1-5/8 | 1.51 | 158 | 174 | 7 |

| 10 x 6 | 10-11/16 | 271 | 6-7/8 | 175 | 6-1/8 | 156 | 0.36 | 4 | 3 | 1/4 | 1-5/8 | 1.63 | 176 | 194 | 7 |

| 11 x 6 | 11-11/16 | 297 | 6-7/8 | 175 | 6-1/8 | 156 | 0.36 | 3 | 4 | 1/4 | 1-5/8 | 1.75 | 194 | 213 | 7 |

| 12 x 6 | 12-11/16 | 322 | 6-7/8 | 175 | 6-1/8 | 156 | 0.36 | 3-3/8 | 4 | 1/4 | 1-5/8 | 1.88 | 212 | 233 | 7 |

| 13 x 6 | 13-11/16 | 348 | 6-7/8 | 175 | 6-1/8 | 156 | 0.36 | 3-5/8 | 4 | 1/4 | 1-5/8 | 1.99 | 230 | 253 | 7 |

| 10 x 7 | 10-15/16 | 278 | 7-15/16 | 202 | 7-1/8 | 181 | 0.38 | 4 | 3 | 5/16 | 1-7/8 | 2.30 | 246 | 271 | 8 |

| 11 x 7 | 11-15/16 | 303 | 7-15/16 | 202 | 7-1/8 | 181 | 0.38 | 3 | 4 | 5/16 | 1-7/8 | 2.51 | 272 | 299 | 8 |

| 12 x 7 | 12-15/16 | 329 | 7-15/16 | 202 | 7-1/8 | 181 | 0.38 | 3-3/8 | 4 | 5/16 | 1-7/8 | 2.68 | 296 | 326 | 8 |

| 13 x 7 | 13-15/16 | 354 | 7-15/16 | 202 | 7-1/8 | 181 | 0.38 | 3-5/8 | 4 | 5/16 | 1-7/8 | 2.83 | 320 | 352 | 8 |

| 14 x 7 | 14-15/16 | 379 | 7-15/16 | 202 | 7-1/8 | 181 | 0.38 | 3 | 5 | 5/16 | 1-7/8 | 2.98 | 345 | 380 | 8 |

| 16 x 7 | 16-15/16 | 430 | 7-15/16 | 202 | 7-1/8 | 181 | 0.38 | 3-1/2 | 5 | 5/16 | 1-7/8 | 3.34 | 400 | 440 | 8 |

| 12 x 8 | 13-1/8 | 333 | 8-15/16 | 227 | 8-1/8 | 206 | 0.40 | 3-3/8 | 4 | 5/16 | 2 | 3.69 | 395 | 435 | 9 |

| 14 x 8 | 15-1/8 | 384 | 8-15/16 | 227 | 8-1/8 | 206 | 0.40 | 3 | 5 | 5/16 | 2 | 4.14 | 470 | 517 | 9 |

| 16 x 8 | 16-1/8 | 435 | 8-15/16 | 227 | 8-1/8 | 206 | 0.40 | 3-1/2 | 5 | 5/16 | 2 | 4.58 | 550 | 605 | 9 |

| 18 x 8 | 19-1/8 | 486 | 8-15/16 | 227 | 8-1/8 | 206 | 0.40 | 3-1/8 | 6 | 5/16 | 2 | 5.04 | 615 | 677 | 9 |

HD-Stax (Low Profile)

| BUCKET SIZE | PUNCHING | WEIGHT, LBS. | CAPACITY, CU. IN. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bucket Size | Length | Projection | Depth | Back Wall Thickness | Centers | # of Holes | Bolt Size | Top Down | HDPE | Water Level | Usable 5 Deg. | Std Spacing | |||

| in. | mm | in. | mm | in. | mm | ||||||||||

| 5 x 4 | 5-5/8 | 143 | 4-5/8 | 118 | 3-1/2 | 89 | 0.32 | 3-3/16 | 2 | 1/4 | 1 | 0.41 | 38 | 40 | 3-1/2 |

| 6 x 4 | 6-5/8 | 168 | 4-5/8 | 118 | 3-1/2 | 89 | 0.32 | 4-3/8 | 2 | 1/4 | 1 | 0.48 | 46 | 48 | 3-1/2 |

| 7 x 4 | 7-5/8 | 194 | 4-5/8 | 118 | 3-1/2 | 89 | 0.32 | 2-5/8 | 3 | 1/4 | 1 | 0.54 | 52 | 55 | 3-1/2 |

| 6 x 5 | 6-3/4 | 172 | 5-3/4 | 146 | 4 | 102 | 0.35 | 4-3/8 | 2 | 1/4 | 1 | 0.69 | 72 | 76 | 4 |

| 7 x 5 | 7-3/4 | 197 | 5-3/4 | 146 | 4 | 102 | 0.35 | 2-5/8 | 3 | 1/4 | 1 | 0.75 | 85 | 89 | 4 |

| 8 x 5 | 8-3/4 | 222 | 5-3/4 | 146 | 4 | 102 | 0.35 | 3-1/16 | 3 | 1/4 | 1 | 0.82 | 103 | 108 | 4 |

| 9 x 5 | 9-3/4 | 248 | 5-3/4 | 146 | 4 | 102 | 0.35 | 3-1/2 | 3 | 1/4 | 1 | 0.90 | 110 | 116 | 4 |

| 8 x 6 | 8-11/16 | 221 | 6-7/8 | 175 | 4-7/8 | 124 | 0.36 | 3-1/16 | 3 | 1/4 | 1 | 1.26 | 140 | 147 | 5 |

| 9 x 6 | 9-11/16 | 246 | 6-7/8 | 175 | 4-7/8 | 124 | 0.36 | 3-1/2 | 3 | 1/4 | 1 | 1.37 | 158 | 166 | 5 |

| 10 x 6 | 10-11/16 | 271 | 6-7/8 | 175 | 4-7/8 | 124 | 0.36 | 4 | 3 | 1/4 | 1 | 1.45 | 176 | 185 | 5 |

| 11 x 6 | 11-11/16 | 297 | 6-7/8 | 175 | 4-7/8 | 124 | 0.36 | 3 | 4 | 1/4 | 1 | 1.61 | 194 | 204 | 5 |

| 12 x 6 | 12-11/16 | 322 | 6-7/8 | 175 | 4-7/8 | 124 | 0.36 | 3-3/8 | 4 | 1/4 | 1 | 1.72 | 212 | 223 | 5 |

| 13 x 6 | 13-11/16 | 348 | 6-7/8 | 175 | 4-7/8 | 124 | 0.36 | 3-5/8 | 4 | 1/4 | 1 | 1.82 | 230 | 242 | 5 |

| 10 x 7 | 10-15/16 | 278 | 7-15/16 | 202 | 6 | 152 | 0.38 | 4 | 3 | 5/16 | 1 | 2.17 | 246 | 258 | 6 |

| 11 x 7 | 11-15/16 | 303 | 7-15/16 | 202 | 6 | 152 | 0.38 | 3 | 4 | 5/16 | 1 | 2.29 | 272 | 286 | 6 |

| 12 x 7 | 12-15/16 | 329 | 7-15/16 | 202 | 6 | 152 | 0.38 | 3-3/8 | 4 | 5/16 | 1 | 2.50 | 296 | 311 | 6 |

| 13 x 7 | 13-15/16 | 354 | 7-15/16 | 202 | 6 | 152 | 0.38 | 3-5/8 | 4 | 5/16 | 1 | 2.63 | 320 | 336 | 6 |

| 14 x 7 | 14-15/16 | 379 | 7-15/16 | 202 | 6 | 152 | 0.38 | 3 | 5 | 5/16 | 1 | 2.76 | 345 | 362 | 6 |

| 16 x 7 | 16-15/16 | 430 | 7-15/16 | 202 | 6 | 152 | 0.38 | 3-1/2 | 5 | 5/16 | 1 | 3.06 | 400 | 420 | 6 |

| 12 x 8 | 13-1/8 | 333 | 8-15/16 | 227 | 6-3/4 | 171 | 0.40 | 3-3/8 | 4 | 5/16 | 1 | 3.41 | 395 | 415 | 7 |

| 14 x 8 | 15-1/8 | 384 | 8-15/16 | 227 | 6-3/4 | 171 | 0.40 | 3 | 5 | 5/16 | 1 | 3.81 | 470 | 494 | 7 |

| 16 x 8 | 16-1/8 | 435 | 8-15/16 | 227 | 6-3/4 | 171 | 0.40 | 3-1/2 | 5 | 5/16 | 1 | 4.23 | 550 | 578 | 7 |

| 18 x 8 | 19-1/8 | 486 | 8-15/16 | 227 | 6-3/4 | 171 | 0.40 | 3-1/8 | 6 | 5/16 | 1 | 4.64 | 615 | 646 | 7 |

Recommended Uses

(Recommended but not restricted to handling these specific products)

Barley

Brown Sugar

Coffee

Corn

Feed

Flour

Grain

Grass Seed

Meat Scap

Nuts

Oats

Pellets

Rice

Salt

Soy Beans

Sugar

Sunflower Seeds

Wheat

Poly

Application:

Grains & Food Products Temperature

Range:

-60F to +180F (210F intermittent)

FDA Approved Material:

Yes

Comments:

Economical, high density polyethylene. FDA approved material for handling food grade products.

ADDITIONAL SPECIAL DRILLING AND VENTING CHARGES

- Drilling any diameter hole over 13/32″

- Bolt Hole centers closer than 1-3/4″

- Side drilled buckets except standard peanut buckets

- Special Venting requirements such as extra holes, change in hole diameter, etc.

- Quoted prices subject to change due to special drilling and venting requirements

#1 Vent

Same holes in body as bolt mounting holes.

#2 Vent

One row of holes on 1-1/8″centers

#3 Vent

Two rows of holes on 1-1/8″centers.

#4 Vent

Same as #3, plus three holes in each end cap.

Custom Vent

Vented as required.

Please call for guidance on bucket venting.

HD-STAX Agricultural Buckets

How Does HD-Stax Stack Up?

Complete your Build

A single shipment, on a single invoice, from a single source: Maxi-Lift. For a limited time only, Maxi-Lift is offering 3% OFF on new bundle orders. Contact us today or call (800) 527-0657 for more information!

Contact a Sales Rep

Subscribe

Join our mailing list to stay up to date with what is happening at Maxi-Lift, Inc.