Template Tape & Power Punch

Ease of installation is a hallmark of Maxi-Splice belt fasteners. We’ve made it easier with the addition of our Template Tape and Power Punch. Each is sized to work specifically for the Maxi-Splice option selected. Having the right tools makes the job go smoothly.

- Overview & Instructions

- Comparison Chart

- Warning

- Media / Literature

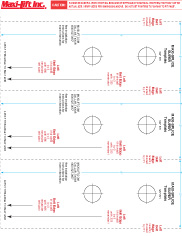

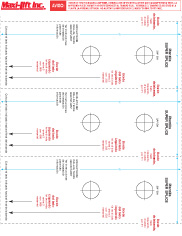

Power Punch

Power Punch

- Made with durable heat treated carbon-steel

- 4 available sizes: 1/2″, 9/16″, 5/8″, and 3/4″ diameter holes

- Use with a hand-held mallet, impact wrench, or drill

- Always wear eye protection

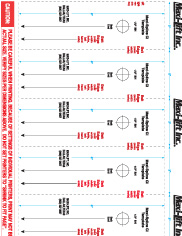

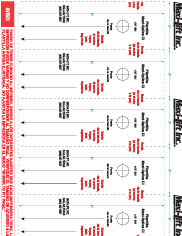

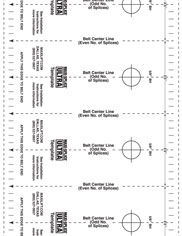

Template Tape – Free

- Peel and stick directly on belt

- Improves belt-punching convenience

- Marks hole locations for odd or even width belts

- Clearly marked in white and red lettering

- Included with every splice order

MAXI-SPLICE TEMPLATE TAPE

View/Print the Comparison Chart (PDF)

Belt Splice Technical Data Sheet

|  |  |  |  |  |

|

|---|---|---|---|---|---|---|

| PART DETAILS | Product | MAXI-SPLICE | MAXI-SPLICE | MAXI-SPLICE | MAXI-SPLICE | MAXI-SPLICE |

| Brand | CI | AB | ULTRA | SUPER | TITAN | |

| Part No | CI5 | AB5 | ULTRA5 | SUPER5 | TITAN | |

| SPLICE CONSTRUCTION | Color | Silver | Manganese Bronze | Silver | Silver | Silver |

| Construction | 3 Piece Mechanical Clamping Device | 3 Piece Mechanical Clamping Device | 3 Piece Mechanical Clamping Device with NBR (Nitrile) Rubber Wedge | 3 Piece Mechanical Clamping Device with NBR (Nitrile) Rubber Wedge | 3 Piece Mechanical Clamping Device with HNBR Rubber Wedge | |

| Metal Material | Galvanized Cast Iron | Manganese Bronze | Aluminum | Aluminum | Aluminum | |

| Metal Description | Ferrous Cast Iron | Non-Ferrous Bronze | High Grade, Lightweight Aluminum | High Grade, Lightweight Aluminum | High Grade, Lightweight Aluminum | |

| Rubber Material | None | None | Replaceable NBR Rubber Wedge | Replaceable NBR Rubber Wedge | Replaceable HNBR Rubber Wedge | |

| SPLICE SPECIFICATIONS | Weight (lbs.) | 2.6 | 2.9 | 1.93 | 4.8 | Per Application |

| Length | 3″ | 3″ | 4-1/2″ | 6-1/4″ | 6″ | |

| Width | 2″ | 2″ | 2-1/2″ | 3″ | Per Application | |

| PIW Rated | Up to 600 PIW Tensile | Up to 800 PIW Tensile | Up to 800 PIW Tensile | 800-1200 PIW Tensile | Over 1200 PIW | |

| Recommended Belt Thickness | 1/4″ to 5/8″ | 1/4″ to 5/8″ | 1/4″ to 5/8″ | 3/8″ to 3/4″ | Per Application | |

| BOLT SPECIFICATIONS | No of Bolts | 1 | 1 | 1 | 2 | Per Application |

| Bolt Grade | Grade 5 Hex Head Bolt | Grade 5 Hex Head Bolt | Grade 5 Hex Head Bolt | Grade 5 Hex Head Bolt | M16 10.9 Hex Head Bolt | |

| Bolt Diameter (Inches) | 1/2″ | 9/16″ | 5/8″ | 3/4″ | Per Application | |

| Bolt Length (Inches) | 5″ | 5″ | 4-1/2″ | 5″ and 5-1/2″ | Per Application | |

| Washers | Yes | Yes | Yes | Yes | Yes | |

| Nuts | Nylock | Nylock | Nylock | Nylock | Oval Lock Nut | |

| Recommended Torque * | 75 ft./lbs | 100 ft./lbs. | 125 ft./lbs. | 150 ft./lbs. | Per Application | |

| Template Tape Included | Yes | Yes | Yes | Yes | Requires Special Template | |

| SHIMS | Required Shims Per Belt Thickness | N/A | N/A | Under 5/16” – No Shims 5/16” to 3/8” – 1 Shim 3/8” to 1/2” – 2 Shims | Under 1/2” – No Shims 1/2” to 5/8” – 1 Shim 5/8” to 3/4” – 2 Shims | N/A |

| TEMPERATURE RATINGS | Max. Operating Temps | 600° F / 350° C | 500° F / 260° C | 200° F / 93° C (NBR Rubber Wedge Limiting Factor) – Alternative Wedges Available for Higher Temperatures | 200° F / 93° C (NBR Rubber Wedge Limiting Factor) – Alternative Wedges Available for Higher Temperatures | 320° F / 160° C (HNBR Hydrogenated Nitrile Butadiene Rubber Wedge Limiting Factor) |

| Nylock Nut Max. Temp | 250° F | 250° F | 250° F | 250° F | 320° F | |

| MINIMUM HEAD PULLEY DIAMETER | Agricultural (High Speed) ** | 12″ | 12″ | 24″ | 30″ | 48″ |

| Industrial (Centrifugal/Gravity) | 12″ | 12″ | 20″ | 36″ | 48″ | |

| BUCKET PROJECTION | Minimum Recommended | 4″ | 4″ | 5″ | 7″ | 8″ |

| FEATURES/ BENEFITS | Strong, Standard, Mechanical Splice | Non-Sparking, Non-Corroding, Non-Rusting | Non-Sparking, Non-Corroding, Non-Rusting, Longer Belt Life | Non-Sparking, Non-Corroding, Non-Rusting, Longer Belt Life | Non-Sparking, Non-Corroding, Non-Rusting, Longer Belt Life |

WARNING: DO NOT USE ANY MAXI-SPLICE ON MANLIFTS!

Please read all instructions before installing any Maxi-Splice product. Instructions can be found at maxilift.com. Failure to follow installation instructions may result in splice failure. As with any belt splice, continuous, regular inspections are required or failure can occur.

Never mix Maxi-Splice products on a single installation. Reduced or uneven clamping pressure may occur compromising splice integrity and could result in splice failure.

Maxi-Lift neither solicits nor recommends the use of any Maxi-Splice belt clamp for splicing man-lift belts. Maxi-Splices were neither designed for nor tested for this purpose. Any installation of a Maxi-Splice product for this purpose may result in splice failure causing serious bodily harm or even death. Do not use on steel cable belts.

Do not reuse nylon insert lock nuts when reinstalling Maxi-Splices. Please use new nylock nuts for reinstallation. Replacements are available from Maxi-Lift.

For applications exceeding 250° F, nylon insert lock nuts may not be used, as this temperature range exceeds the manufacturer’s threshold for nylon integrity. Compression locking nuts should be utilized instead.

While the AB and CI Maxi-Splice may be used on wing pulleys, they may contribute to wear on the backside of the belt at the splice. It is the user’s responsibility to inspect the splice at regular maintenance intervals to prevent failure. Noise may also be heard as the splice contacts the wings of the pulley.

Template Tape Power Punch Belt Splices

Complete your Build

A single shipment, on a single invoice, from a single source: Maxi-Lift. For a limited time only, Maxi-Lift is offering 3% OFF on new bundle orders. Contact us today or call (800) 527-0657 for more information!

Contact a Sales Rep

Subscribe

Join our mailing list to stay up to date with what is happening at Maxi-Lift, Inc.