- Mill Duty, Thick Walls with Reinforced Back & Corners

- Extremely High Impact and Abrasion Resistance

- Applications Up to 600 Degrees

- Designed To Handle Sand, Glass Cullet, Stone, Shot Blast, Rock, Concrete and Other Abrasive Products

- Long Wearing Digging Edge

- Stronger Than Steel of the Same Gauge

- Overview

- Size Chart

- Digger Bucket

- Venting

- Media / Literature

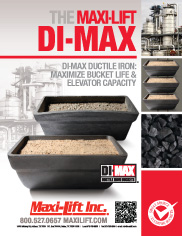

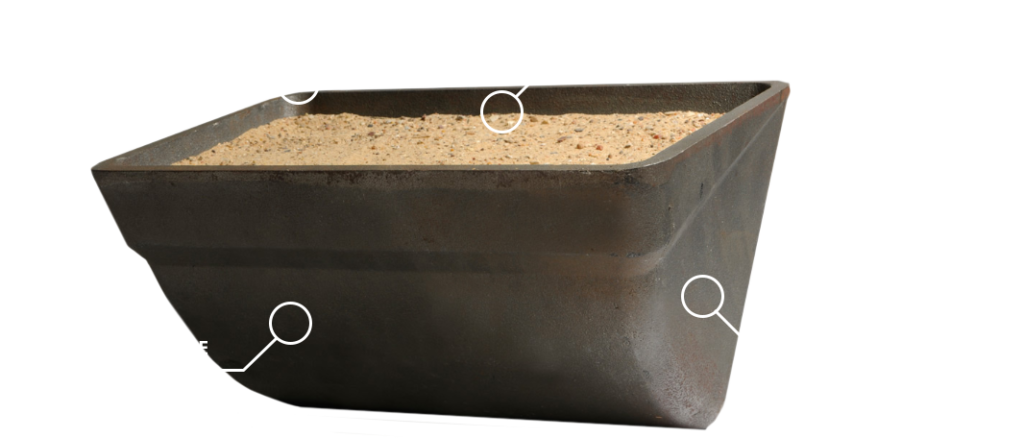

The DI-MAX AA style ductile iron elevator buckets are engineered to exceed the performance requirements of any industrial application. These buckets are designed with thicker walls and a reinforced front lip to increase bucket life in tough industrial environments. Ductile iron is far superior to malleable iron in both impact and abrasion resistance. Replacing malleable iron with DI-MAX ductile iron elevator buckets will result in longer bucket life and more efficient operation.

The DI-MAX AA style ductile iron elevator buckets are engineered to exceed the performance requirements of any industrial application. These buckets are designed with thicker walls and a reinforced front lip to increase bucket life in tough industrial environments. Ductile iron is far superior to malleable iron in both impact and abrasion resistance. Replacing malleable iron with DI-MAX ductile iron elevator buckets will result in longer bucket life and more efficient operation.

FEATURES

- Mill duty, thick walls with reinforced back and corners

- Extremely high impact and abrasion resistance

- Applications up to 600 degrees

- Designed to handle sand, glass cullet, stone, shot blast, rock, concrete and other abrasive products

- DI-MAX has a Brinell hardness of 297

BENEFITS

- Long wearing digging edges

- Stronger than steel of the same gauge

- Smooth surface to ensure proper filling

- Strong impact and abrasion resistance for long life

DI-Max AA Size Chart

| BUCKET SIZE, INCHES | THICKNESS | WEIGHT, LBS. | CAPACITY, CU. IN. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bucket Size | Length | Projection | Depth | Back Wall Thickness | Front Corner Thickness | Front Lip Thickness | Water Level X-X, Cu. In. | Water Level X-X, Cu. Ft. | ||||

| in. | mm | in. | mm | in. | mm | |||||||

| 4 x 3 | 4-1/2 | 102 | 3-3/8 | 86 | 3-1/2 | 89 | .185 | .275 | .250 | 1.7 | 17.1 | 24.2 |

| 6 x 4 | 6-1/2 | 152 | 4-3/8 | 102 | 4-1/2 | 114 | .250 | .350 | .275 | 3.8 | 42.3 | 63.5 |

| 7 x 4 1/2 | 7-1/2 | 191 | 4-3/8 | 114 | 4-1/2 | 114 | .250 | .350 | .275 | 4.0 | 49.5 | 76.2 |

| 7 x 5 | 7-7/8 | 200 | 5-1/8 | 130 | 5-1/2 | 140 | .250 | .250 | .210 | 6.1 | 68.6 | 102.9 |

| 8 x 5 | 8-1/2 | 216 | 5-3/8 | 137 | 5-1/2 | 140 | .250 | .400 | .375 | 6.5 | 83.1 | 126.3 |

| 9 x 5 | 9-1/2 | 241 | 5-3/8 | 137 | 5-1/2 | 140 | .250 | .400 | .375 | 7.5 | 90.7 | 138.8 |

| 11 x 5 | 11-7/8 | 302 | 5-1/4 | 133 | 5-1/2 | 140 | .210 | .250 | .210 | 7.0 | 102.6 | 153.9 |

| 15 x 5 | 15-7/8 | 403 | 5 | 127 | 5-1/2 | 140 | .210 | .400 | .350 | 10.7 | 154.2 | 235.9 |

| 19 x 5 | 19-7/8 | 505 | 5-1/4 | 133 | 5-1/2 | 140 | .250 | .400 | .350 | 14.1 | 198.2 | 303.2 |

| 9 x 6 | 9-5/8 | 244 | 6-3/8 | 162 | 6-1/2 | 165 | .300 | .400 | .375 | 10.2 | 124.7 | 190.8 |

| 10 x 6 | 10-5/8 | 270 | 6-3/8 | 162 | 6-1/2 | 165 | .300 | .400 | .375 | 11.2 | 143.4 | 219.7 |

| 11 x 6 | 11-5/8 | 295 | 6-3/8 | 162 | 6-1/2 | 165 | .300 | .400 | .375 | 12.2 | 159.8 | 244.5 |

| 12 x 6 | 12-5/8 | 321 | 6-3/8 | 162 | 6-1/2 | 165 | .300 | .400 | .375 | 13.1 | 175.4 | 268.3 |

| 12 x 7 | 12-5/8 | 321 | 7-3/8 | 187 | 7-1/2 | 191 | .330 | .625 | .450 | 18.5 | 219.7 | 350.9 |

| 14 x 7 | 14-5/8 | 371 | 7-3/8 | 187 | 7-1/2 | 191 | .330 | .625 | .450 | 20.4 | 265.2 | 407.0 |

| 16 x 7 | 16-5/8 | 422 | 7-3/8 | 187 | 7-1/2 | 191 | .330 | .625 | .450 | 22.9 | 301.2 | 460.9 |

| 14 x 8 | 14-5/8 | 371 | 8-3/8 | 213 | 8-1/2 | 216 | .375 | .625 | .500 | 24.6 | 366.0 | 526.0 |

| 16 x 8 | 16-5/8 | 422 | 8-3/8 | 213 | 8-1/2 | 216 | .375 | .625 | .500 | 26.8 | 381.4 | 599.2 |

| 18 x 8 | 18-5/8 | 473 | 8-3/8 | 213 | 8-1/2 | 216 | .375 | .625 | .525 | 30.0 | 450.3 | 695.0 |

| 20 x 8 | 20-5/8 | 524 | 8-3/8 | 213 | 8-1/2 | 216 | .375 | .625 | .525 | 34.3 | 499.3 | 763.9 |

| 24 x 8 | 24-5/8 | 635 | 8-3/8 | 213 | 8-1/2 | 216 | .375 | .625 | .525 | 42.9 | 597.4 | 914.0 |

| 18 x 10 | 18-3/4 | 476 | 10-3/8 | 264 | 10-1/2 | 267 | .440 | .800 | .750 | 44.6 | 661.5 | 1012.9 |

DI-Max Digger Size Chart

| BUCKET SIZE, INCHES | WEIGHT, LBS. | CAPACITY, CU. FT. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bucket Size | Length | Projection | Depth | 12 Gauge Steel | 10 GA Steel | 7 GA Steel | 1/4″ Steel | Filled to Line X-X | Filled to Line X-Y | |||

| in. | mm | in. | mm | in. | mm | |||||||

| 4 x 3 | 4-3/4 | 121 | 3-3/8 | 86 | 3-1/8 | 79 | 1.35 | 1.80 | 2.35 | – | 0.01 | 0.01 |

| 5 x 4 | 5-3/4 | 146 | 4-3/8 | 111 | 4-1/8 | 105 | 2.25 | 2.65 | 3.50 | – | 0.01 | 0.02 |

| 6 x 4 | 6-3/4 | 171 | 4-3/8 | 111 | 4-1/8 | 105 | 2.75 | 3.25 | 4.20 | 5.50 | 0.02 | 0.05 |

| 7 x 4 | 7-3/4 | 197 | 4-3/8 | 111 | 4-1/8 | 105 | 3.00 | 3.95 | 5.50 | 7.30 | 0.04 | 0.05 |

| 7 x 5 | 7-5/8 | 194 | 5-3/8 | 137 | 5-1/4 | 133 | 3.75 | 4.75 | 6.50 | 8.35 | 0.04 | 0.06 |

| 8 x 5 | 8-5/8 | 219 | 5-3/8 | 137 | 5-1/4 | 133 | 4.25 | 5.45 | 7.15 | 9.45 | 0.05 | 0.08 |

| 9 x 5 | 9-5/8 | 244 | 5-3/8 | 137 | 5-1/4 | 133 | 4.95 | 6.25 | 8.05 | 10.45 | 0.05 | 0.08 |

| 9 x 6 | 9-7/8 | 251 | 6-3/8 | 162 | 6-1/8 | 156 | 6.60 | 7.00 | 9.30 | 12.20 | 0.07 | 0.12 |

| 10 x 6 | 10-7/8 | 276 | 6-3/8 | 162 | 6-1/8 | 156 | 6.10 | 7.70 | 10.10 | 13.35 | 0.08 | 0.13 |

| 11 x 6 | 11-7/8 | 302 | 6-3/8 | 162 | 6-1/8 | 156 | 6.60 | 8.40 | 10.90 | 14.40 | 0.09 | 0.14 |

| 12 x 6 | 12-7/8 | 327 | 6-3/8 | 162 | 6-1/8 | 156 | 7.10 | 9.00 | 11.80 | 15.55 | 0.10 | 0.15 |

| 12 x 7 | 12-7/8 | 327 | 7-3/8 | 187 | 7-1/8 | 181 | 8.75 | 11.05 | 14.55 | 19.05 | 0.13 | 0.21 |

| 14 x 7 | 14-7/8 | 378 | 7-3/8 | 187 | 7-1/8 | 181 | – | 12.35 | 16.35 | 21.45 | 0.15 | 0.24 |

| 14 x 8 | 14-7/8 | 378 | 8-3/8 | 213 | 8-1/8 | 206 | – | 14.35 | 19.30 | 25.45 | 0.21 | 0.33 |

| 16 x 8 | 16-7/8 | 429 | 8-3/8 | 213 | 8-1/8 | 206 | – | 16.05 | 21.30 | 28.25 | 0.24 | 0.38 |

| 18 x 8 | 18-5/8 | 473 | 8-3/8 | 213 | 8-1/8 | 206 | – | 17.55 | 23.30 | 30.80 | 0.27 | 0.43 |

| 18 x 10 | 19 | 483 | 10-3/8 | 264 | 10-1/8 | 257 | – | 22.05 | 29.45 | 39.40 | 0.35 | 0.66 |

Venting an elevator bucket aids in bucket fill and discharge with light, fluffy materials.

Lightweight, fluffy materials, those that are extremely dense or flow poorly can be difficult to handle in bucket elevators at high speeds. Because these materials tend to trap air when being handled by an elevator bucket, venting provides air relief to assist in their filling and discharge. Commodities for venting include flours, meals, feed mash, DDG’s or screenings. As these materials enter the bucket, air is released through a series of vent holes in the bottom of the bucket allowing for a more complete fill. These vent holes also allow air to re-enter the bucket, which facilitates full release of product into the discharge.

Standard hole diameter is equal to the size of the bolt mounting holes in vent pattern #1, all other vent patterns will have 11/32” diameter holes unless otherwise requested by the customer.

When elevating powdery materials such as cement in the Tiger-Tuff, a minimum of two rows of 3/8″ diameter vent holes are recommended to help ensure that the material will discharge cleanly.

ADDITIONAL SPECIAL DRILLING AND VENTING CHARGES

- Drilling any diameter hole over 13/32″

- Bolt Hole centers closer than 1-3/4″

- Side drilled buckets except standard peanut buckets

- Special Venting requirements such as extra holes, change in hole diameter, etc.

- Quoted prices subject to change due to special drilling and venting requirements

#1 Vent

Same holes in body as bolt mounting holes.

#2 Vent

One row of holes on 1-1/8″centers

#3 Vent

Two rows of holes on 1-1/8″centers.

#4 Vent

Same as #3, plus three holes in each end cap.

Custom Vent

Vented as required.

Please call for guidance on bucket venting.

DI-Max AA Industrial Buckets

There’s Ductile Iron, Then There’s Maxi-Lift Ductile Iron

The DI-MAX AA bucket performs at the top of its class.

Complete your Build

A single shipment, on a single invoice, from a single source: Maxi-Lift. For a limited time only, Maxi-Lift is offering 3% OFF on new bundle orders. Contact us today or call (800) 527-0657 for more information!

Subscribe

Join our mailing list to stay up to date with what is happening at Maxi-Lift, Inc.