Engineering

Take advantage of Maxi-Lift’s online technical support tools including answers to most common elevator bucket questions and useful technical support charts.

Engineering Application

Technical Charts

Scroll through to find the technical chart for your needs.

Technical FAQ’s

Having trouble? Read our FAQs to find helpful answers to the most commonly asked questions. If you need further assistance, please call us at (800) 527-0657, Email Us or fill out our form below.

Length: The bucket length is measured at the back mounting surface. Lay the bucket on it’s back for actual measurement dimensions from end to end.

Projection: Projection is measured vertically to the lip as it would project from the belt or chain. With the bucket still lying flat on its back, measure up to the highest point of the bucket lip.

Depth: Depth is measured for the overall side profile dimension. Again, with the bucket lying flat, measure the from top to bottom of the back of the bucket.

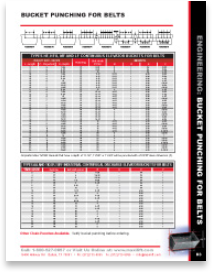

#1 Vent: Same number of holes in the body as the mounting holes

#2 Vent: One row of holes on 1-1/8” centers.

#3 Vent: Two rows of holes on 1-1/8” centers.

#4 Vent: Same as #3, plus three holes in each end cap.

Custom Vent: Special vent patterns as requested.

If you aren’t sure which to choose, reach out to the Maxi-Lift team for guidance.

Bucket application – what is the material being elevated and what is the temperature?

Bucket size – what are the measurements of the current buckets?

Bucket material – is the bucket polyethylene, nylon, urethane, ductile iron, carbon steel or stainless steel?

Does the bucket need to be low-profile?

Does the bucket need venting holes?

What is the mounting bolt hole pattern?

What style of bucket is needed? – please consult the Maxi-Lift website to see all the styles available.

Fill out the Maxi-Lift Elevator Bucket Selection Sheet for complete information.

If plastic buckets are attached to a static conductive belt with steel (conductive) bolts and the belt travels over conductive pulleys that are part of a properly grounded bucket elevator, the system will safely conduct any static electricity that’s generated.

There’s no historical evidence that plastic buckets have ever caused a spark that led to a dust explosion.

Plastic buckets have been in use since the 1950s.

Plastic buckets won’t cause a spark even when they meet an obstruction.

None of the Maxi-Lift poly materials (polyethylene, urethane and nylon) can generate a sufficient volume of electric charge to produce a blue static spark.

- Maxi-Lift recommends the use of a cordless drill or impact driver that has an adjustable clutch system to manage torque. For a demonstration see our YouTube Video below.

- Set the clutch mechanism to a lighter torque setting to begin.

- Attempt to tighten the fasteners on the first bucket using this light torque setting. If this setting results in seating the bolt just flush into the back cover, then proceed. If it does not seat the head into the cover, or pulls it in too deeply, then adjust the clutch so the desired result is achieved. You are looking to just get the head flush into the cover.

- Working left to right, repeat the process until you get a consistent result. Once you consistently get the bolt heads to seat, complete the remaining bucket installation, alternating the direction on each consecutive bucket to avoid causing the belt to bow out.

- Do not overtighten the bolts, as this will cause high spots or humps between the bolts. These high spots will become wear points on the belt and will wear out before the rest of the belt.

Technical Help

Thanks for visiting Maxi-Lift, Inc.! We want to hear from you. Please fill out the form below and we will reply promptly!

This report and the analysis or recommendations contained herein are provided to the current or former customers of Maxi-Lift, Inc., DuraPlas, Inc., and/or their respective subsidiaries or affiliates (collectively, the “Company”) at no additional or separate charge to the recipient. This report was generated based on the information and data points provided by the recipient and output generated by the Company’s simulator software program, but not based on any actual results. This report is being provided only for the internal use of the recipient in assessing potential improvements or corrective actions to its current processes and/or equipment configuration and shall not be shared or provided to any third parties without the express written consent of the Company. The Company is providing this report on an as-is, where-is basis, and makes no representations, warranties or guarantees whatsoever with respect to the report, its content or any information provided by the recipient.

THE COMPANY MAKES NO WARRANTY WHATSOEVER WITH RESPECT TO THE REPORT OR SERVICES, INCLUDING ANY (A) WARRANTY OF MERCHANTABILITY; OR (B) WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE; OR (C) WARRANTY OF TITLE; OR (D) WARRANTY AGAINST INFRINGEMENT OF INTELLECTUAL PROPERTY RIGHTS OF A THIRD PARTY; WHETHER EXPRESS OR IMPLIED BY LAW, COURSE OF DEALING, COURSE OF PERFORMANCE, USAGE OF TRADE, OR OTHERWISE.

The recipient further acknowledges and agrees that it accepts any and all risks associated with its content or any action taken by the recipient whether based in whole or part on any contents of this report. Under no circumstances will the Company be blamed for, or accept any liability for, any loss or damage of any kind arising out of the use of all or any part of this report.

IN NO EVENT WILL THE COMPANY BE LIABLE TO THE RECIPIENT FOR: (A) ERRORS OR OMISSIONS IN ANY CONTENT PROVIDED BY THE COMPANY, OR (B) ANY LOSS OF USE, REVENUE, OR PROFIT OR FOR ANY CONSEQUENTIAL, INCIDENTAL, INDIRECT, EXEMPLARY, SPECIAL, OR PUNITIVE DAMAGES, WHETHER ARISING OUT OF BREACH OF CONTRACT, TORT (INCLUDING NEGLIGENCE), OR ANY OTHER LEGAL THEORY, REGARDLESS OF WHETHER SUCH DAMAGE WAS FORESEEABLE AND WHETHER OR NOT SUCH PARTY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Subscribe

Join our mailing list to stay up to date with what is happening at Maxi-Lift, Inc.